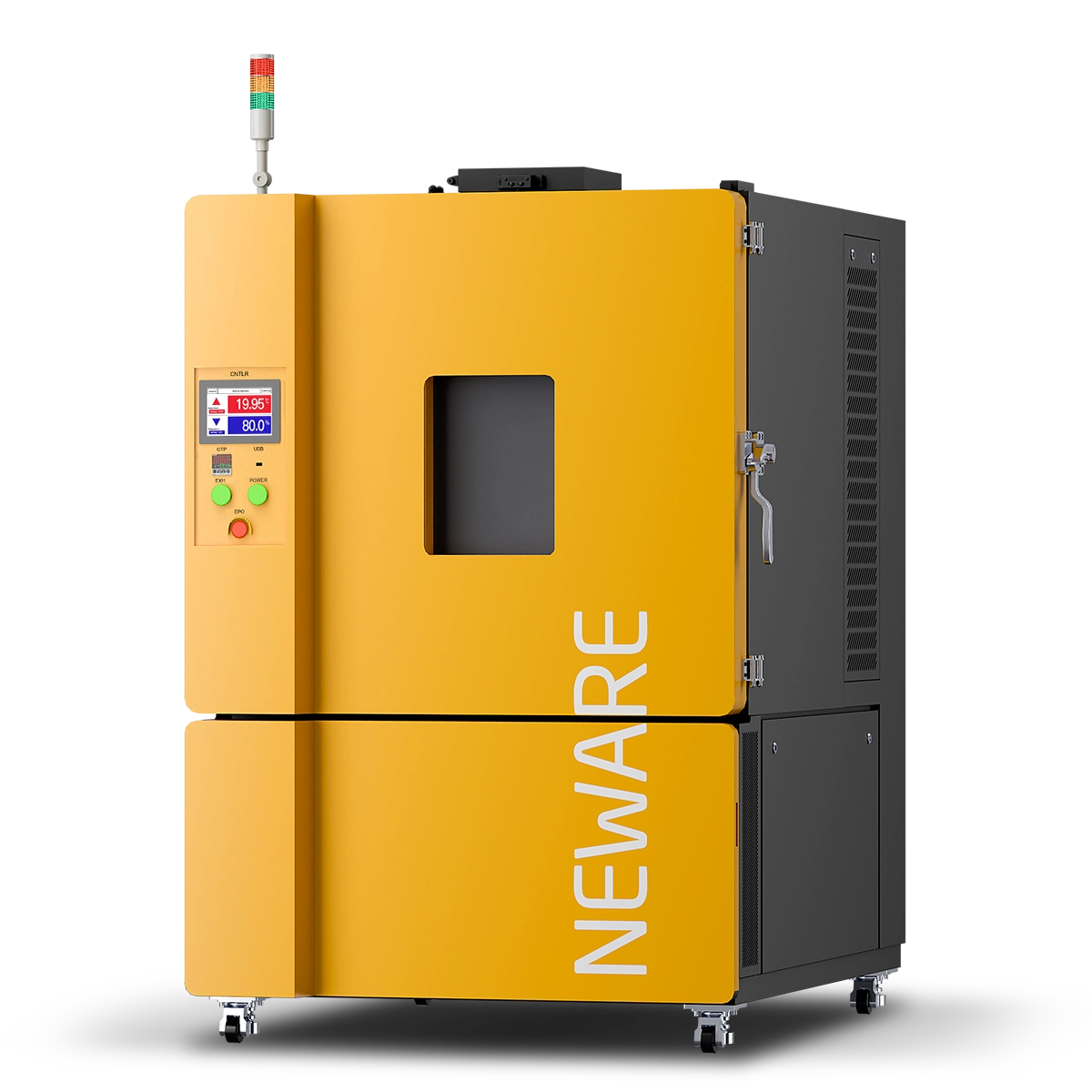

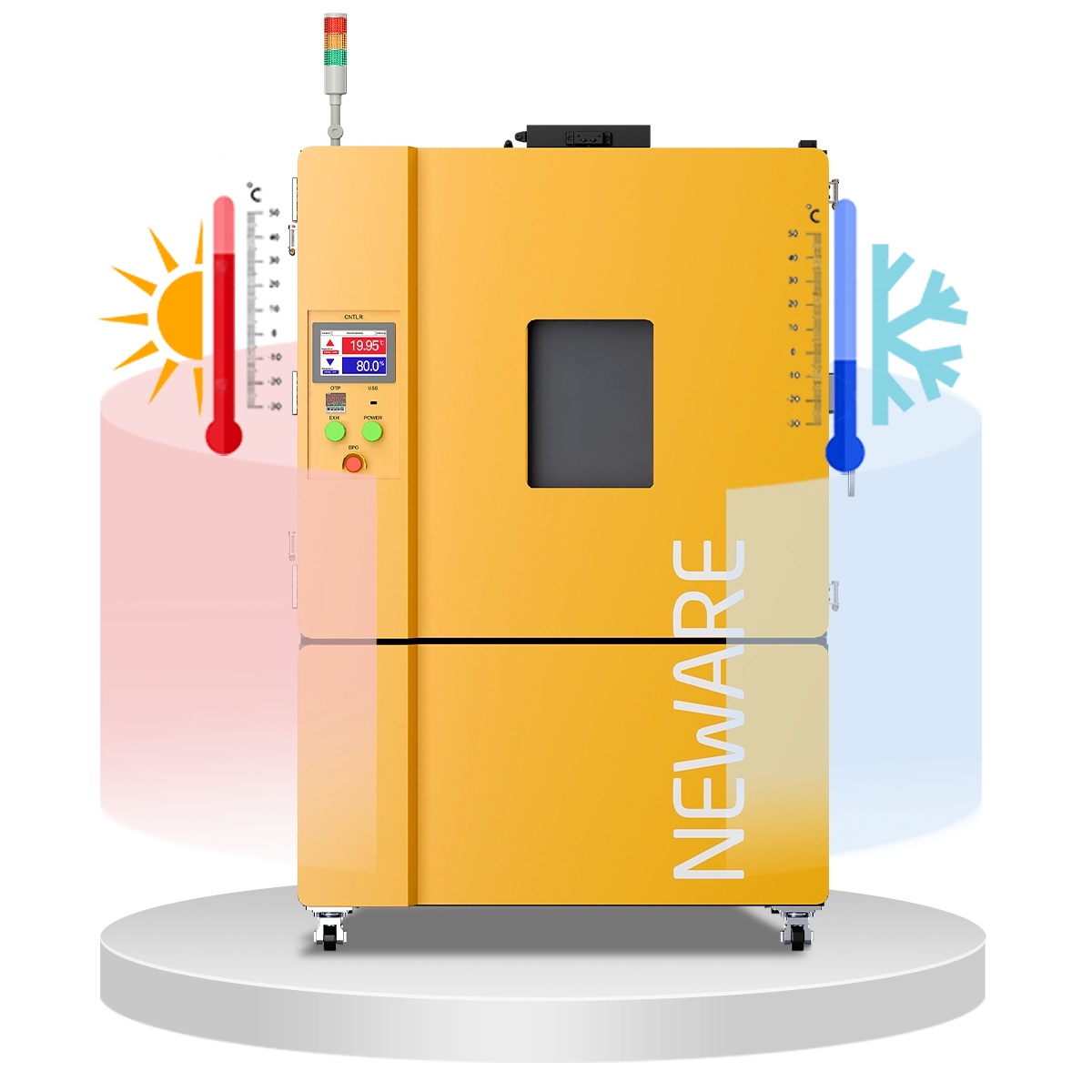

WGDW-400L-40BC-5V30A96CH not only connects to BTS testing systems, efficiently processes large-scale data and complex computational tasks, meeting various high-performance computing requirements, but also provides high and low temperature experimental temperatures. Test battery performance changes at different temperatures. The explosion-proof feature creates a safe testing environment for battery cell testing,

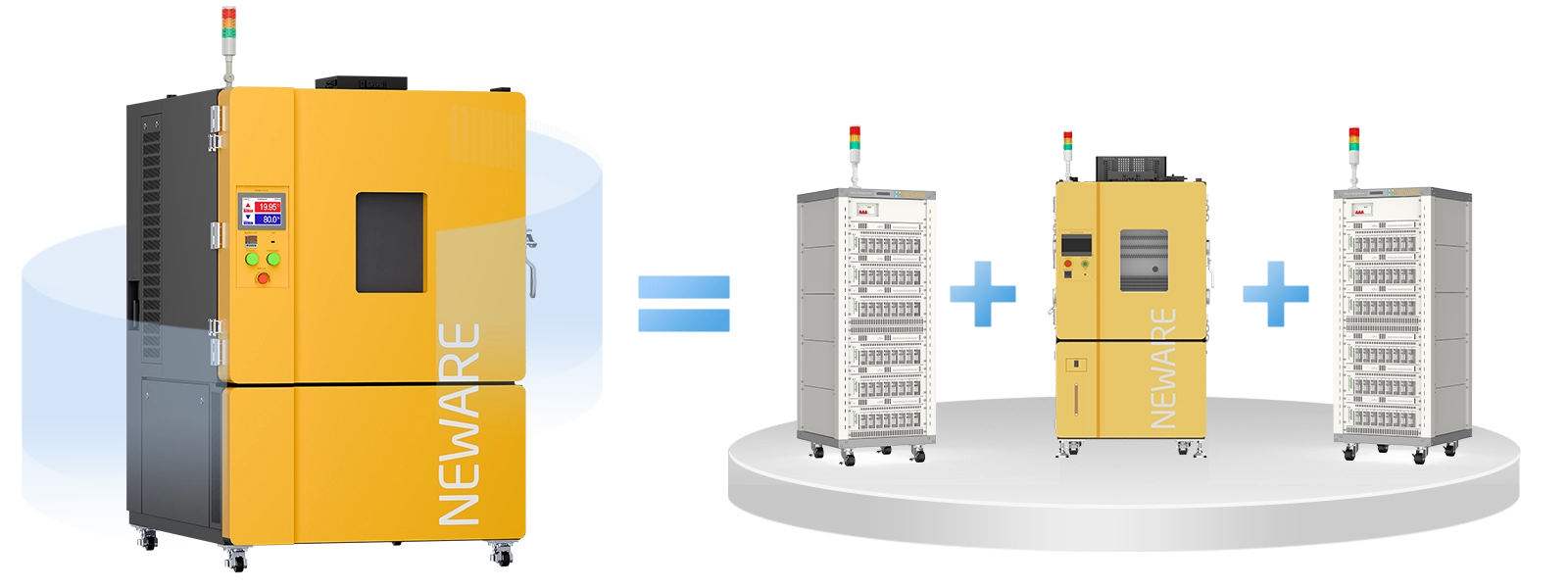

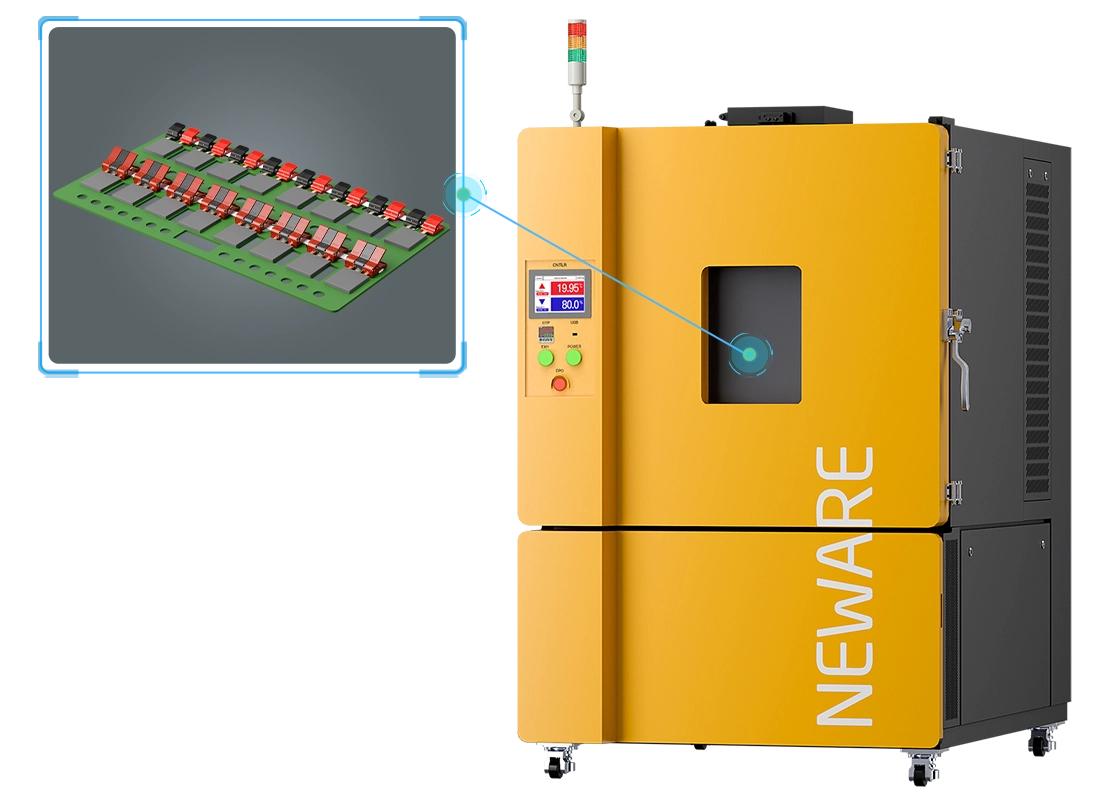

Integrating the charging and discharging detection equipment with the high and low temperature environmental test chamber, this integrated testing system not only saves valuable laboratory space but also significantly improves the efficiency of equipment use. By connecting to the BTS battery testing system, it achieves unified control over battery testing and temperature conditions, making the operation more convenient.

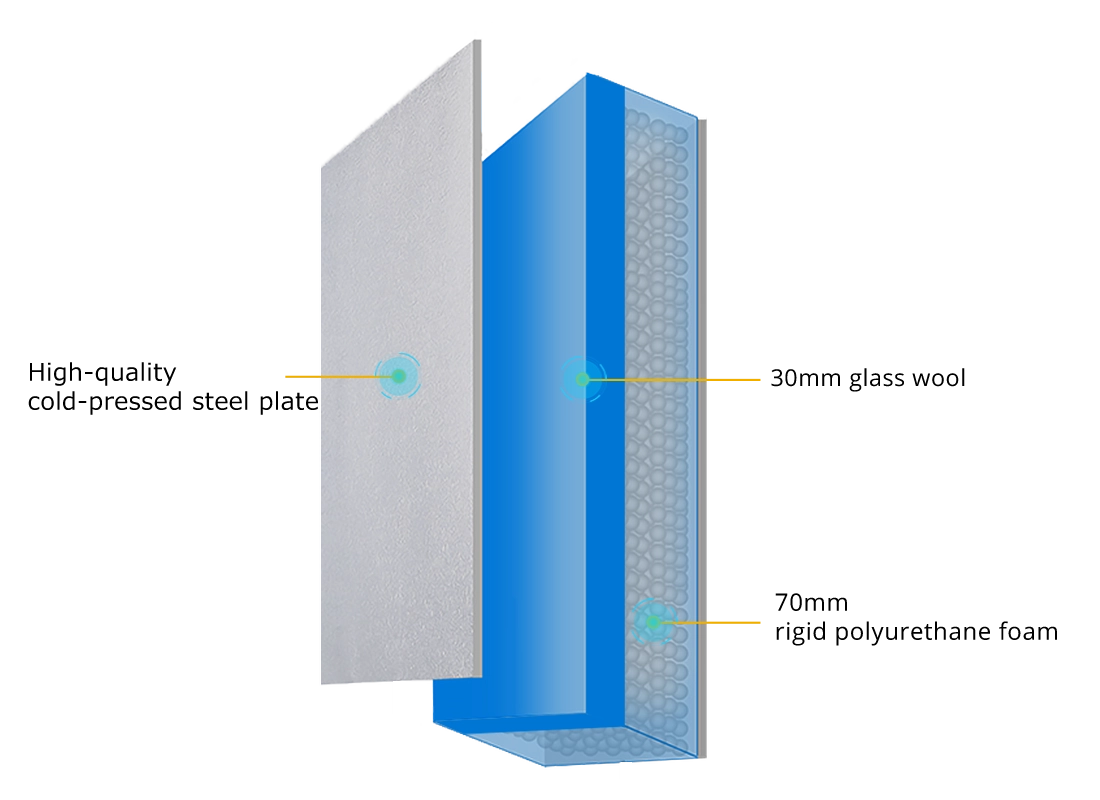

The exterior wall material is made of high-quality cold-pressed steel plate, and the insulation structure consists of a 100mm insulation layer composed of rigid polyurethane foam and glass wool. This insulation layer effectively isolates the internal and external environments, preventing heat exchange and keeping temperature fluctuations within the range of ±0.9℉(±0.5℃).

Battery trays adopt high-temperature resistant insulation material, ensuring compatibility with a wide range of batteries. The height, orientation, and placement position can be adjusted accordingly, making it suitable for various sizes and specifications of square cells testing requirements. Maximum capacity for 96 battery cells for synchronous testing.

By adopting a mechanical compression folding refrigeration method and equipping a fully enclosed piston refrigeration compressor, the system operates in an environmentally friendly manner with low noise. The self-developed temperature control module has undergone reliable performance testing for high and low-temperature impact, vibration, EMC, and other related reliability aspects, exhibiting a robust and sensitive temperature control capability.

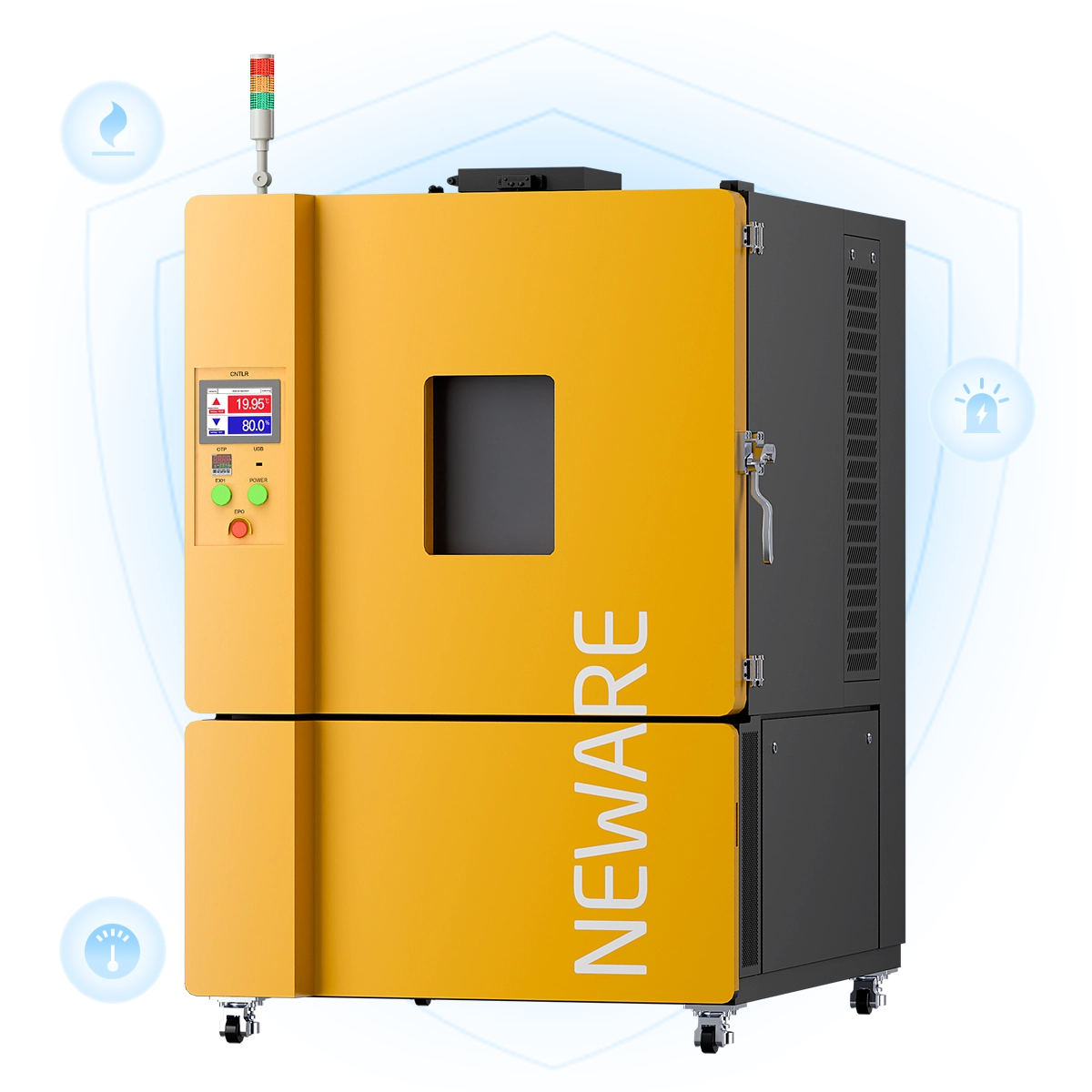

Explosion-proof venting port automatically opens when the pressure in the test chamber exceeds the set pressure.

Smoke detector automatically triggers the smoke exhaust fan when detecting excessive smoke concentration.

Prioritizing user experience, the design incorporates a touch LCD display with a friendly graphical user interface and flexible configuration options, allowing users to easily set up and manage the equipment. The interface also includes buttons for fire protection, over-temperature protection, and smoke exhaust control, enabling users to operate safety measures with just a few simple steps.

● Leakage protection

● Short circuit protection

● Offline testing

● Power failure recovery protection

● Adjustable over-temperature protection

● Abnormal operation protection for circulating fans

The software is fully functional, covering a variety of work-step settings, recording, and data storage to meet a wide range of testing needs.

Integrated peripheral devices such as Auxiliary Voltage, Auxiliary Temperature for comprehensive testing and evaluation, providing multi-dimensional and quantifiable support for battery mass production testing.